Encoders and hall-ICs are important drive components

Encoders

Magnetic or optical encoders pick up mechanical movements directly on the shaft of a BLDC or DC motor in order to convert them into digital or analog signals. An encoder counts motor rotations for speed measurement or the direction of rotation for motion sequences.

Hall-IC

A hall sensor uses the strength of a magnetic field to detect the approach of the permanent magnet in the electric motor and sends out its electrical signals. A hall-IC can also be part of an encoder.

Drive components for customized motor concepts

JBW supplements customer-specific motor concepts with encoders, hall-ICs, encoder boards or rotary encoders - depending on what the specification for the drive solution requires.

Fields of application for encoders and hall sensors

Encoders and hall sensors record such measured values in the motor and transmit electrical signals to the controls. They therefore support crucial tasks in many areas of application, e.g. here:

Robotics, conveyor technology, CNC machines

Position detection for controlling grippers or in fast pick-and-place systems on assembly lines.Automotive industry

Speed measurement for precise speed control for ABS systems, gears or electric servo steering systemsMedical technology

for devices for the precise dosing of medicines and active ingredients

Attributes and functions of an encoder and hall-IC

Attributes of encoders and hall-ICs on electric motors

- Non-contact measurement - no mechanical wear

- High precision - for accurate position and speed measurement

- Fast response times - ideal for fast switching operations and high rotation speeds

- Compact design - space-saving and easy to mount on motors

- Permanent magnetic field measurement - independent of light conditions or mechanical wear

Encoder / hall-IC functions

- Speed measurement on BLDC and DC motors for precise rotation speed control

- Rotor position determination on BLDC motors for correct control of the windings

- Commutation as a replacement for mechanical brushes in brushless motors

- End position and position detection for robotics, conveyor technology or CNC machines

- Current sensors for the indirect measurement of electrical currents through magnetic fields

- Safety and monitoring functions for checking machine movements

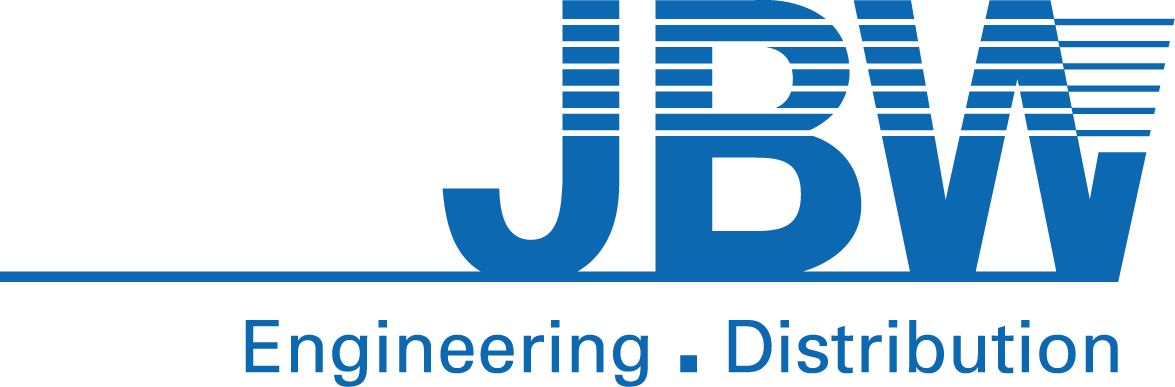

Hollow shaft encoder

- Sensor housing with hollow shaft open on one side

- This hollow shaft encoder is available from JBW and is installed in the worm gear motor series GMPG motor type404.329.0040.

Technical Data

Type: Incremental

Pulses per revolution: 100, optionally from 1 to 5,000

Frequency response: max. 200 kHz

Rotation speed at the shaft: max. 12,000 rpm

Channels: 3 (A, B, Z)

Dimensions: Diameter 16 mm

Height: 20 mm

Voltage: 5 V

Current consumption: 35 mA

Hollow shaft: 3.0 mm

Protection category: IP54

Weight: 15 g

Temperature: max. 85 °C

Item no.: 100.216.0010

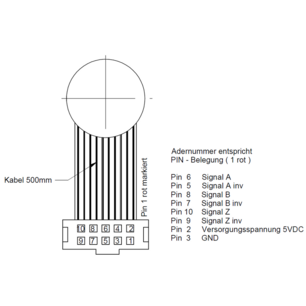

Circuit board with fork light barrier

- For use on rotating shafts that are equipped with a dividing disk. This disk runs centrally in the fork light barrier.

- Depending on the disk used, the photoelectric sensor can generate from 1 to 48 pulses per shaft revolution.

- This circuit board with fork light barrier is in stock at JBW and is installed in the worm geared motor series SWMK motor type 404.987.0011.

Technical data

Type: optical

Pulses per revolution: max. 48, depending on the used graduated disk

Channels: 1 (A)

Dimensions: 43 x 30 mm

Height: 13 mm

Voltage: 17.5 - 30 V

Current consumption: 70 mA

Protection category: IP00

Weight: 100 g

Temperature: max. 55 °C

Article no.: 100.108

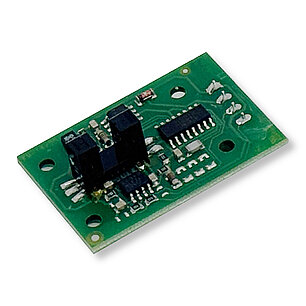

Universal encoder board for electric motors

- Encoder board with integrated magnetic sensor and digital signal processing

- Version for rotation speeds of up to 120,000 rpm

- High-resolution position determination (up to 1024 pulses/revolution)

- RS422-compatible AB signals with index track Z

- Configurable resolution, hysteresis, edge distance, zero position and rotation direction

- This encoder board is a JBW in-house development. It is installed in the worm gear motor series GMPG motor type 404.306.0022.

Technical data

Type: magnetic

Pulses per revolution: 256

Channels: 2 (A, B )

Dimensions: Diameter 40 mm

Height: 11 mm

Voltage: 5 V

Protection category: IP00

Weight: 13 g

Item no.: 100.147.0050

Encoder / Rotary encoder / Incremental encoder

- Encoder in multi-part housing for mounting on electric motors or at shaft ends

- Pitch disk available in different pitches and for different diameters

- Application: Worm gear motors of the DCK/SWMK/SW2K/SW2L series, if the armature shaft can be extended.

- For automated systems in industrial robotics, medical technology, textile machines, length measuring systems, etc.

Technical data

Type: optical

Pulses per revolution: 512

Channels: 2 (A, B)

Dimensions: 40.8 x 30.8 mm

Height: 17 mm

Voltage: 5 V

Protection category: IP00

Weight: 13 g

Item no.: 100.278.00XX

Hall-IC circuit board

- Circuit board with two hall-ICs, connection cable, protective cap and magnet

- The round magnets are available for different shaft diameters and numbers of poles.

- This circuit board is available for most spur gear motors and planetary gear motors .

- JBW installs this hall-IC in the planetary gear motor series P044066 motor type P044066.0014.14.

Technical data

Type: Hall-IC

Pulses per revolution: max. 14

Channels: 2 (A, B)

Diameter in mm: 12 / 22 / 30 / 32 / 36 / 42.5 / 52 / 54

Height: 8 mm

Voltage: 12 V

Protection category: IP00

Weight: 9 g

Article no.: 100.248.00XX

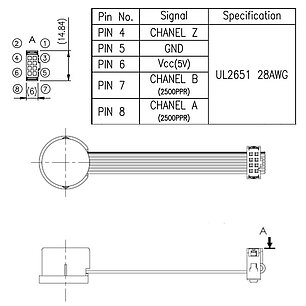

Magnetic encoder on planetary gear motor P044066

- Magnetic encoder on planetary gear motor series P044066

- Resistant to dust, oil and vibrations

- Compact case, suitable for small motors

- Software configurable

- For applications with high demands on positioning accuracy and robustness.

Technical data

Type: magnetic

Pulses per revolution: 2,500

Channels: 3 (A, B and Z)

Voltage: 5 VDC

Specification for each encoder and hall-IC

Tell us what you want your drive system to do. We will be happy to help you select the right BLDC or DC motor and work with you to specify which values an encoder should tap for motor control at the motor.

The encoders listed here are some examples that we have developed and produced to customer specifications. Give us your required specification and together we will find the best solution.