Drive test bench for DC and BLDC motors

Special service for correct selection and equipment of drive technology

On the JBW GmbH motor test bench, characteristic curves for current, voltage, rotation speed, torque and temperature are read in and processed in order to evaluate the load capacity and functionality of a DC motor or BLDC motor.

Together with the measurement data of the application-specific load characteristics, which are recorded on the prototype via a digital storage oscilloscope, a DC or BLDC geared motor optimized for the application can ultimately be put together.

Brake types on the test bench

- Magnetic particle brake from 0.5-50 Nm up to 1,000 rpm

- Hysteresis brake from 0-6 Nm to 10,000 rpm

Measuring channels

- Current

- Voltage

- Rotation speed

- Torque

- Temperature

Examinations

- Characteristic curve recording

- Reverse torque (static and dynamic)

- Temperature test

- Endurance test

- Freely programmable test cycle

Characteristic curves - revealing the motor characteristics

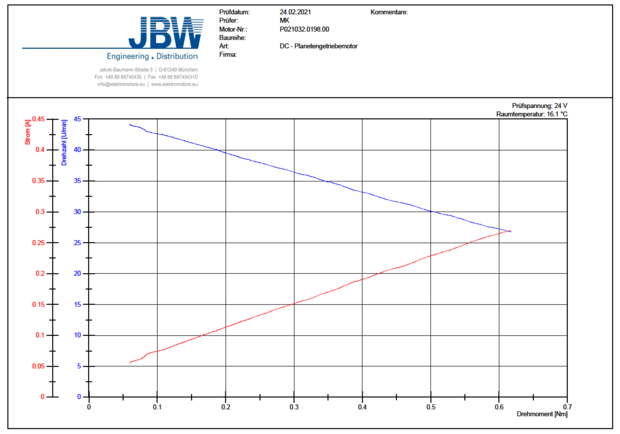

We have created this characteristic curve for the planetary gear motor P021032.0198.00.

What do you see on a motor characteristic curve?

Here, the X-axis shows the torque, the right Y-axis the rotation speed (blue) and the left Y-axis the current consumption (red).

Every DC geared motor on the JBW drive test bench is increasingly loaded with a brake and therefore slows down (the blue rotation speed line decreases). In order to continue turning, an electric motor draws more current (the red line increases). Using the characteristic curve created in this way, it is easy to see how the respective motor behaves at which torques. In other words, how fast it is and how much current it consumes in each case.

Why are the motors not always braked to the end, i.e. until rotation speed 0 is reached and the torque is at its highest?

Not every gear can withstand so much torque. With particularly large ratios, there is even a risk of destroying the gear. Every gear has its own nominal and maximum torque.

How do you determine the rated torque of a motor?

The nominal torque is not a fixed point for electric motors, but rather a range. The nominal torque range is approx. 1/3 of the maximum torque. It is of course possible to operate the motors up to the defined maximum torque for a short time.

What happens to the characteristic curve when the voltage is increased or reduced?

If the voltage is increased or reduced, the rotation speed curve moves up or down almost proportionally. This means, for example, that if the voltage is only 12V instead of 24V, the rotation speed drops by 50%.