Dependable Partner for Electric Drive Systems

"Technically mature, individually composed and economically feasible“

JBW GmbH is recognized by their industrial customers as their reliable engineering and distribution partner for complete electric drive systems. High-quality DC motors of different types and performance classes, various drives, motor controls, and toroidal transformers as well as associated mechatronic components are among our assemblies and reflect our core competence in engineering. All our drive systems are procured customer-oriented and delivered in-time relying on an in-house store. Our customers benefit from short reaction periods, high supply availability and flexibility. These combined strengths are relevant for customers in medical and rehab engineering, in mechanical and plant engineering as well as in tool making.

JBW participates in SPS Italia 2024

Italy is the second largest automation market in Europe and we are therefore happy to offer our BLDC / DC geared motors and drive solutions there too.

The right DC gear motor in just three steps

You need the right DC gear motor for your application.

You need the right DC gear motor for your application. Based on your specification, we will suggest the optimal geared motor. In addition to detailed schemes and characteristics, we also provide load case results from our drive test bench.

Based on your specification, we will suggest the optimal geared motor. In addition to detailed schemes and characteristics, we also provide load case results from our drive test bench.

Electric motors | Our product catalog in drive systems

As an experienced supplier in drive systems, we develop, integrate and modify electric motors, gearboxes, motor controls and other assemblies in order to meet almost all your requirements.

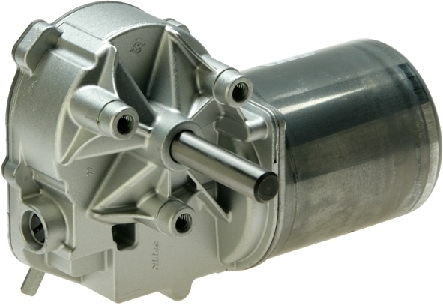

Worm gear motors

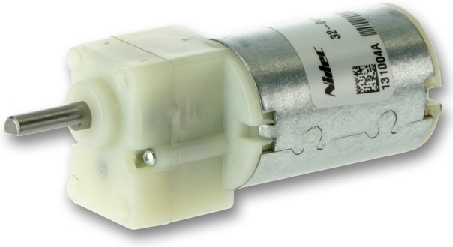

Spur gear motor

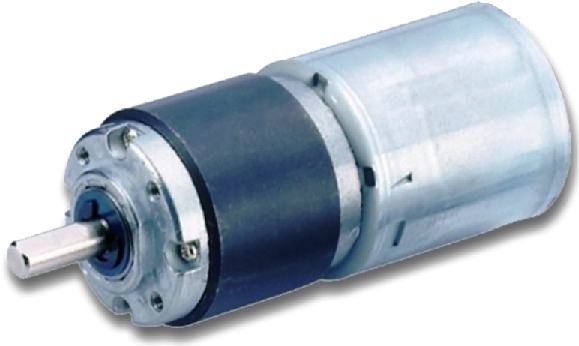

DC motors with spur gear units are ideally used in all drive systems with parallel drives (central or decentralized gear shaft outlets), as well as at higher torques and lower speed. In addition, these are decisive criteria: a spur geared motor is powerful and yet space-saving, which can be crucial in a small installation space of e.g. office equipment and laboratory equipment.Planetary gear motors

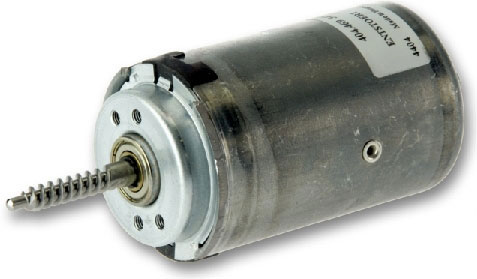

BLDC Motors

A brushless DC Motor (for short: BLDC motor) is powerful and particularly durable, because they run mechanically without brushes and other wear parts. The compact design, which fits to almost every small installation space, shows a higher power density compared to brushed DC motors. For these reasons, a BLDC motors is often applied to medical technology and robotics systems.DC Motors without Gearbox

High-Torque BLDC Motor

The new technology of this high-torque BLDC motor opens up new dimensions in drive technology: In combination with the case-relevant gearboxes, this motor with its small dimensions and weight achieves a very high degree of efficiency. It runs extremely steady, smoothly and quietly and guarantees a long service life. This patented motor technology combines the advantages of classic DC motors with fully electronic commutation. The integrated electronic control with encoder covers a wide range of applications – and that with little implementation effort. This motor characteristic is well described with powerful, precise and without cogging torque. Finestly adjusted performance for systems and devices in laser technology and medical technology.Motor Controls

Toroidal Transformers

We produce our own low-noise toroidal transformers in common standard designs especially for applications in control technology and in plant and device construction. They promise high efficiency, low power loss and optimal temperature behavior. On request, we can also supply you with special versions of other sizes, capacities or with additional magnetic or electrostatic shielding. And always applies: Each toroidal transformer is manufactured and tested in accordance with the applicable guidelines for safety transformers.

Engineering | Our Development Services for Drive Systems

Are you looking for the right motor for your application or do you need a completely new drive concept? Do you want to improve or adapt an existing drive system? Our engineers are specialized in such questions regarding drive technology and mechatronic automation. With our extensive product and system knowledge and many years of experience in drive technology with electric motors, gearboxes and controls, we stand by our industrial customers solution-oriented and reliably. We see ourselves as your engineering partner.

Drive Adaptation

Mobile Measurements

Our industrial customers call us for help when their customers report unexpected problems with series devices, in which they install our electric motors. We diagnose the problem based on the cause and often use it to quickly identify the only correct solution. Our expertise is also in demand when it comes to deciding on the right electrical drive technology in prototyping. We provide clear, undeniable facts with our measurements.

Drive Test Bench – Dedicated Test Systems

Kinematics Concepts

As so often, the key lies in the configuration and motion sequence, which is why we are glad to support you in the development of application-specific kinematics concepts. It has to be identified in each detail, how the desired performance can be optimally correlated with the drive technology used. Be it a television in the luxury segment, a bathtub lift or a production machine – we test for a snapshot with a mobile measurement at the customer's site or with endurance tests in our own rooms. Then we can tell you exactly, whether and how far the pre-selected components of the drive technology match with the requirements of the respective application. This provides valuable insights for prototypes as well as series devices. It is documented in detail, which forces act and when it e.g. unintentionally comes to an early shutdown. Our engineers think along how motion sequences and the drive technology used would be optimally harmonized.

Assembly

Use Cases | Automation in Industries and Home

- Industrial automation and robotics

- Office equipment and household appliances

- Plant engineering and pump technology

- Special vehicle construction and agricultural machinery

- Mechanical engineering

- Energy technology

- Image and measurement data acquisition

- Medical technology and rehabilitation technology

Recognized Benefits

- Engineering and distribution from a single source

- Wide product portfolio of DC geared motors

- All components for complete drive systems

- Drive modules – checked and logged

- Engineering support – development, testing, optimization

- High supply availability thanks to large in-house warehouse

We do a lot to remain a strong partner in drive systems

Long-term customer-supplier relationships provide stability

Mirko Wilden

Owner and CEO

"Our industrial customers, like us, appreciate a trustful and constructive cooperation. Solutions in drive systems nowadays require the skilful combination of high-quality electric motors, optimal gears, intelligent motor controls and a wide range of variations in all associated components. In addition, the best technical solutions also require reliably agreed delivery capability. You get all of this from us - from JBW GmbH in Munich."

I look forward to your call >> Tel. +49 89 89745430

Elektric Motors and Drive Systems | Questions and Answers

Which geared DC motor is particularly durable?

It always depends on the application. A brushless DC motor with fewer wear parts has its advantages as well as a robust worm gear motor. But there are different ways to achieve a long service life, e.g. by designing the lubrication of the geared motors depending on the application.

How do I get CAD data for a DC geared motor?

On request, we provide you with the associated CAD data for all our electric motors, as well as motor characteristics, circuit and connection data. Please, send us an email to info@elektromotore.eu with your contact details and which DC motor you need the CAD model for.

Depending on the order volume, you will get our best price.

Depending on the order volume, you will get our best price.