DC motors without gear are available in different variants. The product filter can be used to quickly find the right DC motor for the specific application where gears are available. Gears may already be permanently installed in the application for cost reasons or to minimize gear backlash, but where flexibility in motor selection is required. For example, to be able to work at high rotation speeds, as is the case with pump variants, or where the accuracy of the laser technology requires it.

Product Filter

No match for the required drive component here?

Oh, then we have not yet included the right product for your requirement criteria in our online product database

But maybe in our warehouse after all!

We have almost countless types of DC motors and drive components on offer and many are even available in stock. Or we can assemble the complete drive system specifically for your application. We would be happy to work with you to consider which configuration might provide the optimal drive. Just talk to us directly!

With the M042022 and the M043022 we have introduced a new motor type in our product category motors without gear product category. Both are BLDC motors. They are special in that they are external rotor motors. Their crankcase is made of metal, they operate in the left/right direction with 24 Voltage, a rated power of 41 or 19.6 Watt and at an idle speed of 6710 or 3800 rpm. Their nominal torque is 0.083 or 0.075 Nm.

We can generally offer you these 24V external rotor motors:

- From 22 mm to 92 mm diameter

- From 3 to 260 watts of rated power

- Up to 9000 rpm

- Almost all of them can be equipped with a gear.

What is the difference in motor design between an external rotor motor and an internal rotor motor?

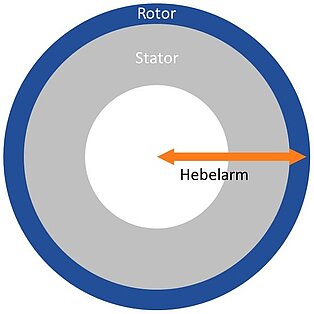

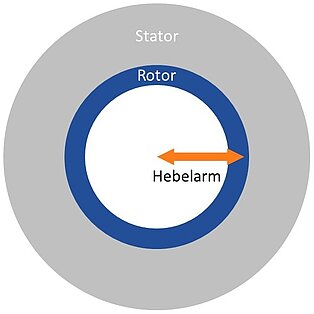

An external rotor motor consists of a stator with coils and a rotor with permanent magnets. In an internal rotor motor, the usual BLDC motors, the magnets are mounted on the axle, which rotates on the inside of the stator coils (motor pot). With this external rotor motor, on the other hand, the magnets are attached to the motor pot on the outside of the stator coils. For this reason, it is not just the axle that rotates in these motors, but the entire motor pot (housing). In addition, the air gap is smaller in external rotor drives because there is no rotor bandage. This air gap between the rotor and stator also influences the surface thrust and thus the torque and rated power.

What are the advantages of an external rotor motor?

The decisive advantage of an external rotor motor is the longer lever arm, as the force is generated further away from the center of rotation. The longer lever arm leads to higher torque. As a result, an external rotor motor can achieve far greater torques than an internal rotor motor with a comparable construction volume. An internal rotor motor is often designed with gears in order to achieve the desired torque level. However, the gear leads to a larger installation volume, mechanical losses and often to lower accuracy. So if the installation space is very limited and a high torque is required, an external rotor motor is often a good choice.

DC motor without gearbox | Your questions & answers

JBW operates an extensive engine test bench in Munich, with which we can also put third-party engines through their paces and compare them with the requirements. Based on the performance data determined, we can usually offer you a suitable replacement engine.

Most of the DC motors in the JBW product portfolio are in a power range of up to 500 watts.

Most of our DC motors are operated with 24V DC or 12V DC. However, depending on the application, other voltages are also possible.

JBW sources our DC motors from both Europe and Asia.