Worm Gear Motors - always a good choice

Robust, economical and reliable

Applications

Engine construction, automated engines, agriculture technology, office machines, medical and rehab engineering, traffic and communication technology, photographical/optical equipment, etc.

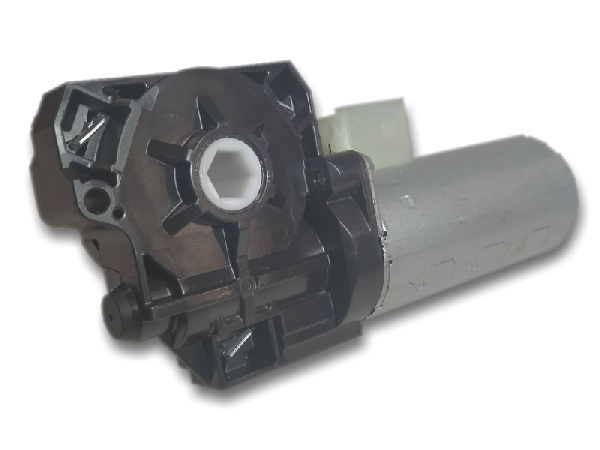

New in the product catalog | Worm gear motor CM3G series

The new CM3G series currently includes two motor types. Both have a diameter of only 33.8 mm, making them our smallest worm geared motors. They are extremely compact and flat, yet extremely powerful and with an effective self-locking of over 10 Nm (CCW). The hollow shaft is a simple hexagon socket. A two-channel Hall IC is built into the motor.

Applications

This motor series can be used in all applications that need the advantages of a worm gear motor, but only have a small installation space. They would be very suitable, for example, in height-adjustable tables.

Technical key data

Most of the structural criteria of this CM3G series correspond to the usual key data for worm geared motors. The motor housing is roller burnished and protected against corrosion. One anchor bearing is a plain bearing, the other a spherical bearing. The gear housing and gear wheel are made of plastic and need grease for permanent lubrication. Both electric motors rotate right and left.

The CM3G motor types differ from one another in the left or right gear position, the drive shaft and in the nominal voltage of 12 or 24 volts. They provide a speed of 125 or 240 revolutions per minute with the same nominal torque of 4 Nm and a tightening torque of 12 or 14 Nm.

Modifications

Depending on the application, attachments like encoders, tachometers or brakes are required and can be carried out. Just like the assembly of add-on parts specified by the customer, for example coupling, rubber-metal buffers or mounting brackets for installation.

The right worm gear motor in just three steps

You need the right worm gear motor for your application. Your must-have criteria: quiet and with a certain amount of self-locking.

You need the right worm gear motor for your application. Your must-have criteria: quiet and with a certain amount of self-locking. You receive the ideal worm gear motor matching your specification. You get all the detailed drawings and characteristics. On request, we can also test it on our drive test bench.

You receive the ideal worm gear motor matching your specification. You get all the detailed drawings and characteristics. On request, we can also test it on our drive test bench. Depending on the order volume, we will give you our best price for this worm gear motor.

Depending on the order volume, we will give you our best price for this worm gear motor.

Worm gear – a closer look

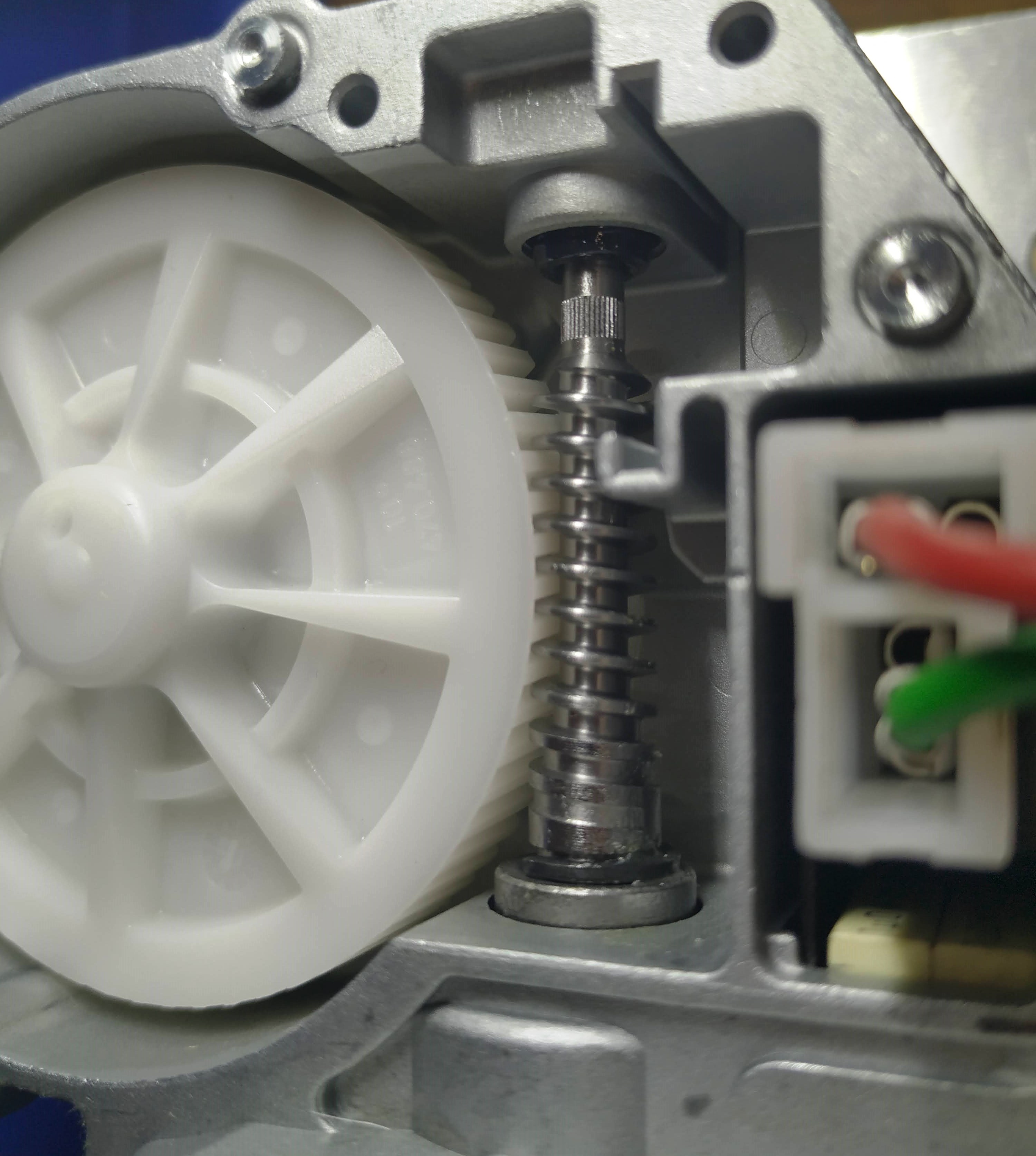

Worm shaft and worm wheel

Worm Gear

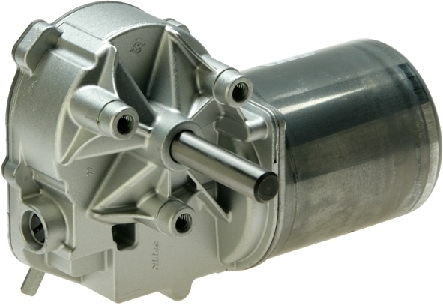

Motor Series DCK 31

Here in the picture you can see the worm gear motor 404.864 of the DCK 31 series. The armature speed is approx. 5000 rpm and the worm shaft rotates identically. Thanks to the gear ratio of 1:69, the motor shaft reaches a speed of around 70 rpm. The gear ratio is calculated from the number of teeth on the worm wheel and the number of turns on the worm shaft.

Reduced sliding friction

Our manufacturer and supplier of complete worm gear motors, the Japanese NIDEC Group, skillfully copes with the increased demands on the production process in terms of precision and surface quality, because these two criteria together reduce friction. Because of the sliding friction, the worm and worm wheel are also made of different materials: The worm, which is subject to greater wear, is made of e.g. hardened steel, while the worm wheel is often made of softer materials such as brass, bronze or a self-lubricating plastic. During continuous operation, a suitable lubricant ensures that the heat is removed which develops due to the low efficiency at high gear ratios.

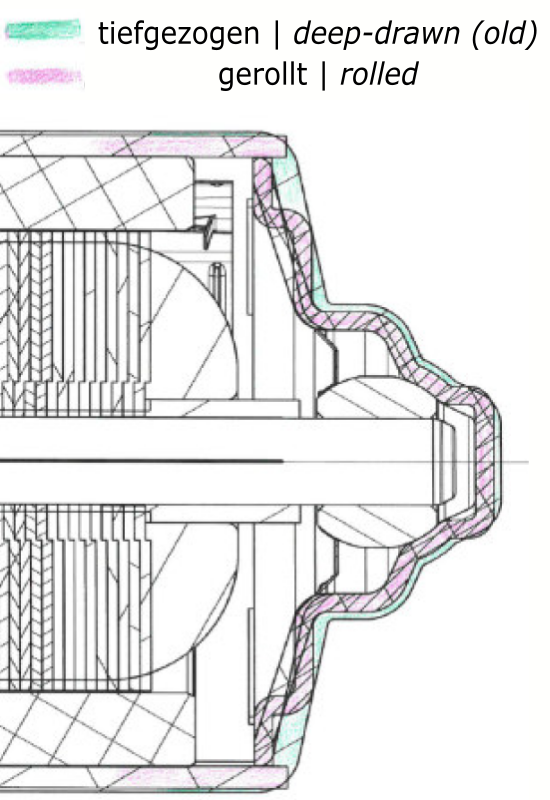

14.02.2020 | New DCK motor housing

>> More about the new DCK motor housing

We invest a lot to stay a strong partner for drive systems